Autoclaves 101

Autoclaves are an unsung hero of modern medicine, scientific research, and industrial manufacturing. In this blog post, we'll dive deep into the world of autoclaves - exploring their history, regulations, real-world applications, and best practices for operation and maintenance.

What is an autoclave?

An autoclave is a powerful tool used to sterilize equipment, materials, and waste by using high-pressure steam. It's commonly found in hospitals, laboratories, and industrial settings to kill bacteria, viruses, fungi, and spores that could contaminate instruments, materials, and or waste.

Why are autoclaves vital?

Autoclaves are essential because they ensure proper sterilization, which is critical in medical, scientific, and industrial settings. Without them, contamination risks would skyrocket, leading to infections, failed experiments, or compromised manufacturing processes.

How long have autoclaves been around?

The concept dates back to 1679, when Denis Papin invented the steam digester, a precursor to the modern autoclave. However, the first true autoclave was developed in 1879 by Charles Chamberland, a French microbiologist working with Louis Pasteur. Since then, autoclaves have evolved significantly, incorporating advanced sterilization techniques and improved safety features.

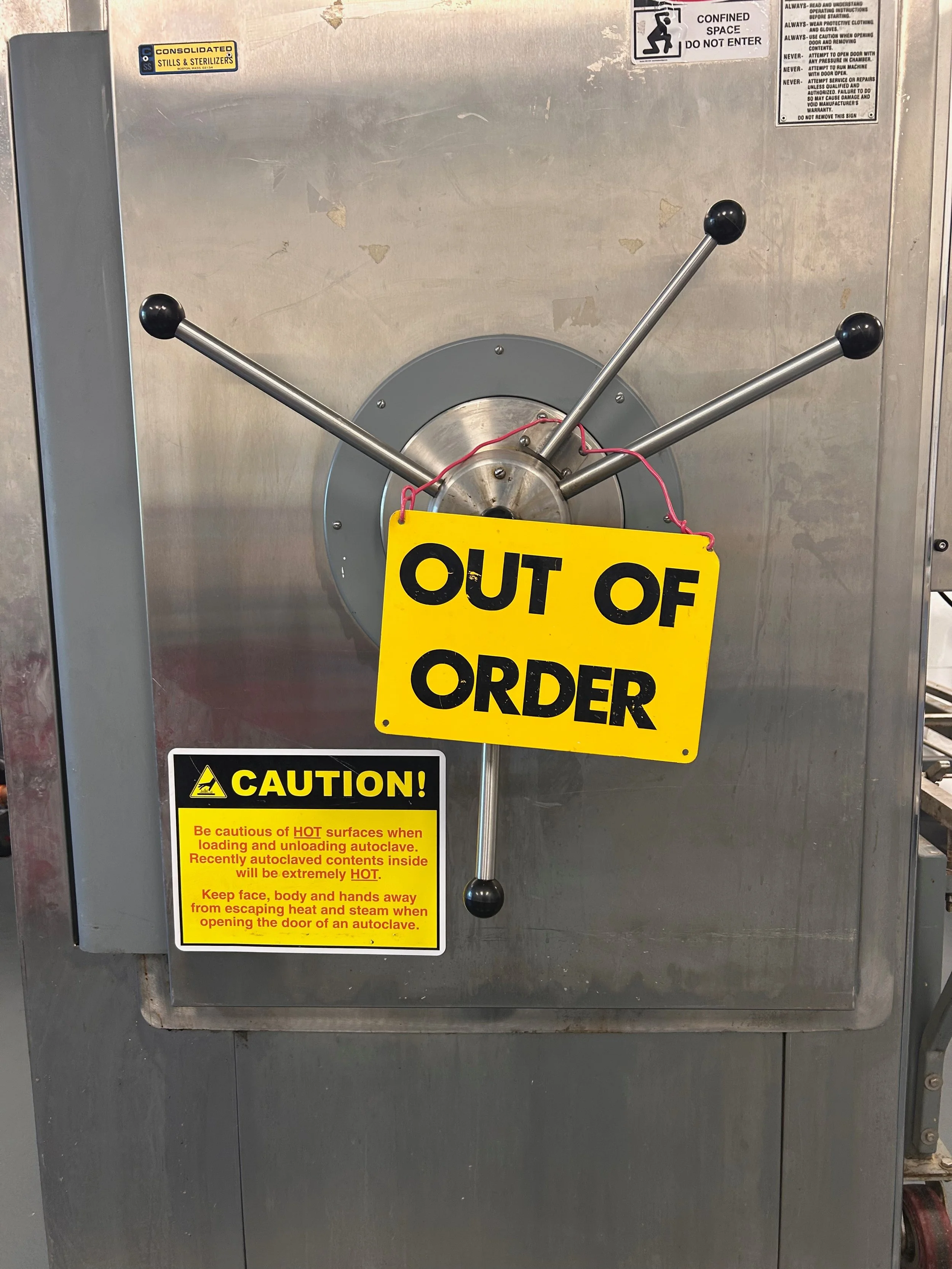

Who manufactures autoclaves?

There are many manufacturers of autoclaves worldwide, each specializing in different industries like medical, laboratory, dental, and industrial sterilization. Some well-known manufacturers include Tuttnauer, which has been in the industry since 1925, and Beta Star Life Science Equipment, which focuses on biopharma and laboratory sterilization. Getinge, Consolidated, and Primus are three of the other big-name manufacturers that all specialize in building autoclaves for laboratories, medical facilities, and research applications. These autoclaves can come in all different sizes, from tabletop to the size of a large closet.

Why is it important that you hire a well-trained professional team to service your autoclave?

Hiring a trained autoclave mechanic is crucial because autoclaves are complex, high-pressure sterilization machines that require precise maintenance and repairs to function safely and effectively. Here’s why expertise matters:

Safety: Autoclaves operate at high temperatures and pressures, and improper repairs can lead to steam leaks, explosions, or equipment failures that pose serious risks.

Efficiency & Longevity: A trained mechanic ensures that the autoclave is running optimally, reducing downtime and extending its lifespan.

Proper Diagnosis: Autoclave issues can be tricky—whether it’s a faulty seal, pressure sensor failure, or inconsistent sterilization—but an expert knows how to pinpoint problems and fix them correctly.

Regulatory Compliance: Many industries, especially healthcare and laboratories, require autoclaves to meet strict sterilization standards. A trained mechanic ensures that your autoclave is certified and operating within regulations.

Preventative Maintenance: Routine servicing by a professional prevents costly breakdowns, avoiding unexpected repairs or potential contamination risks.

Having a knowledgeable technician handle your autoclave protects both your equipment and the people relying on it for sterilization.

How do autoclaves sterilize?

Autoclaves sterilize using pressurized steam to eliminate bacteria, viruses, fungi, and spores. The process works through heat, moisture, and pressure, ensuring thorough sterilization. Here’s how it happens:

Steam Generation: Water is heated to produce steam, which fills the autoclave chamber.

Temperature & Pressure Increase: The system raises the temperature to 121-134°C (250-273°F) and pressure to around 15-30 psi, making conditions lethal for microorganisms.

Exposure Time: Items remain in the chamber for 15-30 minutes, allowing heat and moisture to penetrate and destroy most pathogens.

Cooling & Drying: Once sterilization is complete, pressure is released, and the items dry to prevent contamination.

What are autoclaves constructed of?

Autoclaves are primarily made of stainless steel, which is durable, corrosion-resistant, and able to withstand high temperatures and pressure. Different components serve specific functions:

Chamber – Usually 316L stainless steel, designed to hold items being sterilized and resist corrosion from steam and chemicals.

Doors & Seals – Made from high-strength alloys and heat-resistant gaskets to ensure a secure, airtight seal.

Pipes & Valves – Often brass, copper, or stainless steel, allowing steam and pressure to flow properly.

Insulation & Outer Casing – Includes thermal insulation materials and reinforced steel to retain heat and ensure safety.

Control System – Electronic components and sensors regulate temperature, pressure, and sterilization cycles.

Are autoclaves pressure vessels?

Yes, autoclaves are considered pressure vessels because they operate under high-pressure steam to achieve sterilization. A pressure vessel is any container designed to hold gases or liquids at a pressure higher or lower than ambient pressure, and autoclaves fit that definition perfectly.

Since they generate high-temperature steam under pressure, autoclaves must meet strict engineering and safety regulations to ensure they don’t rupture or malfunction. Many autoclaves are built according to ASME Boiler & Pressure Vessel Code standards, ensuring they can safely handle extreme conditions.

Their classification as pressure vessels means they require routine inspections, maintenance, and safety features to prevent hazards like steam leaks or pressure failures.

What sizes do autoclaves come in?

Autoclaves come in a wide range of sizes, depending on their intended use. Here are some common categories:

Small tabletop autoclaves – Ideal for dental offices, small labs, and tattoo parlors. Chamber sizes typically range from 7-23 liters

Medium-sized autoclaves – Used in hospitals, research labs, and pharmaceutical settings. These can range from 50 to 200 liters.

Large industrial autoclaves – Found in manufacturing, aerospace, and large-scale medical facilities. These can exceed 500 liters, with some models reaching several cubic meters in capacity.

Some manufacturers offer customizable chamber sizes to fit specific sterilization needs.

How do I choose the right size autoclave for my facility?

Choosing the right size autoclave depends on what you're sterilizing, how often, and your available space. Here’s how to narrow it down:

1. Determine Your Load Size

Small (7-23L) → Ideal for dental clinics, tattoo parlors, small labs with limited tools.

Medium (50-200L) → Great for medical facilities, research labs, and universities handling frequent sterilization.

Large (500L and above) → Used in industrial, pharmaceutical, and manufacturing for high-volume or large item loads.

2. Check Your Available Space

Ensure ventilation, plumbing, and electrical needs match the autoclave size.

Some facilities custom-build autoclave rooms for industrial models.

3. Industry Requirements

Medical & research → Strict sterilization protocols may require specific chamber sizes.

Manufacturing & industrial → May need high-capacity units for bulk processing.

As the user, what should I be doing before I start and run a cycle?

Before running an autoclave cycle, users should conduct a pre-check to ensure safe and effective sterilization. Here’s a checklist to follow:

Inspect the Autoclave

Ensure vents & drains are clear – A blocked vent can cause dangerous pressure buildup.

Verify water levels – Make sure there’s enough distilled water for steam generation (for specific models.)

Properly Load Items

Avoid overloading – Steam must circulate freely to sterilize effectively.

Place items correctly – Arrange instruments, glassware, or waste for maximum exposure.

Use proper containers – Autoclavable bags, trays, and wraps should be suitable for high-heat sterilization.

Select the Correct Cycle

Choose the right temperature & time based on materials (e.g., wrapped tools vs. liquid sterilization).

Confirm pressure settings match the autoclave’s requirements for proper sterilization.

Check documentation for any specific sterilization needs based on lab or medical regulations.

Safety Measures

Wear protective gear – Heat-resistant gloves and safety goggles prevent burns.

Ensure emergency exits are accessible – In case of malfunctions, users should be able to respond quickly.

Confirm door locks engage properly – A loose seal can cause steam leaks, sterilization failure, or failure to start a cycle.

Operating an autoclave demands attention to detail and routine safety checks.

What are some of the most common autoclave cycle failures?

Failure to Reach Temperature – If the autoclave doesn’t reach the required sterilization temperature, it could be due to a faulty steam generator, clogged chamber drain, incorrect settings, or building utility issues.

Pressure Problems – Difficulty maintaining pressure can result from leaks, faulty seals, blocked vents, a clogged chamber drain screen or building utility issues.

Incomplete Sterilization – Overloading the chamber or improper arrangement of items can prevent steam from circulating properly, leading to ineffective sterilization.

Door Seal Failures – A damaged or improperly sealed door gasket can cause steam leaks and prevent the autoclave from maintaining pressure.

Load Damage – Items may melt or experience liquid boil-over if they are not autoclave-safe or if the cycle settings are incorrect.

Unusual Noises – Strange sounds during operation may indicate mechanical issues, such as failing pumps or steam traps.

Routine maintenance and proper loading techniques can help prevent these failures.

Our team of autoclave experts is always happy to provide guidance, answer technical questions, or offer recommendations on the right equipment for your facility's needs. Whether you're looking to purchase a new autoclave, need assistance with proper maintenance and operation, or are simply curious to learn more, we're here as a resource. Autoclaves play a crucial role in numerous industries, and ensuring they operate safely and effectively is of the utmost importance. So please, connect with us by phone or email - we're here to help in any way we can.